A method that dramatically speeds up carbon dioxide sequestration and also aids in the extraction of critical minerals from mine tailings will make its way from a Michigan Technological University lab to regional mines.

The project, to help mines in Michigan’s Upper Peninsula and Minnesota achieve net-zero emissions while extracting critical minerals from mine tailings, has received $2.5 million from the U.S. Department of Energy (DOE).

The DOE awarded grants to develop rapid carbon mineralization and critical mineral extraction technology to 16 projects nationwide, totaling $39 million. Michigan Tech’s project is the only one in the state to receive funding from Mining Innovations for Negative Emissions Resource Recovery (MINER), a new initiative through the DOE’s Advanced Research Projects Agency-Energy (ARPA-E). The MINER initiative funds technology research that increases mineral yield, while decreasing required energy and subsequent emissions, in order to mine and extract energy-relevant minerals.

Michigan Tech’s project is titled “Energy Reduction and Improved Critical Mineral Recovery from Low-Grade Disseminated Sulfide Deposits and Mine Tailings.” It seeks to permanently and cleanly mineralize and store carbon dioxide, potentially enabling the mining industry in Michigan’s Upper Peninsula and Minnesota to achieve net carbon zero while extracting critical minerals from low-grade ores, said principal project investigator (PI) Lei Pan, an associate professor in Michigan Tech’s Department of Chemical Engineering. Chemical engineering professors Tim Eisele and David Shonnard are co-PIs on the three-year project, along with researchers from University of Utah and University of Nevada, Reno.

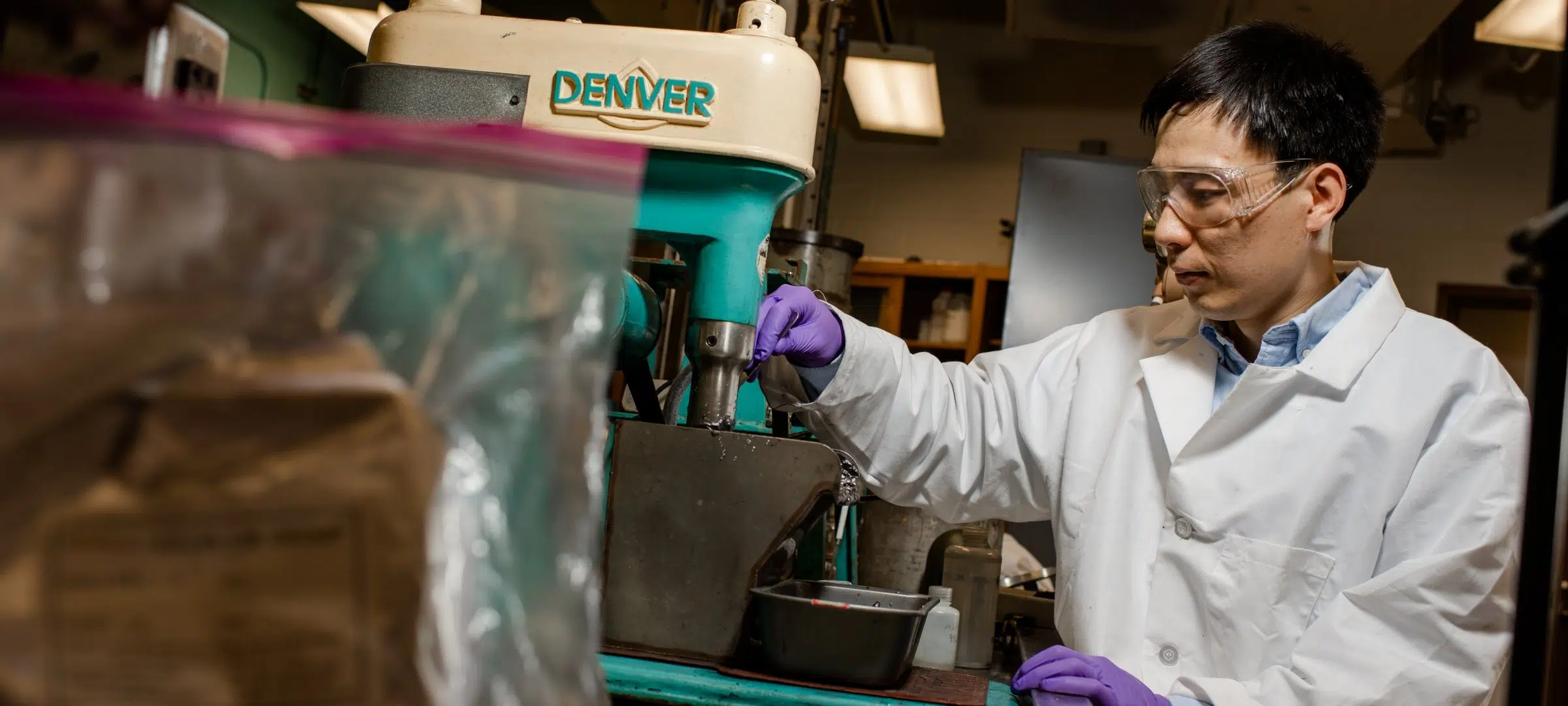

Kobina Ofori, a Ph.D. student in chemical engineering, serves as student investigator. Chemical engineering undergraduate student Katie Liberman is also assisting in the work, which takes place in Pan’s Lab for Separation Technologies (LAST) at Michigan Tech.

“MINER research targets potential carbon-dioxide-reactive ores to unlock net-zero or net-negative emission technologies,” Pan explained. “We will take carbon dioxide from the mining operation and store it safely and permanently in minerals. With our technology, we estimate 2.2 million tons of carbon dioxide per year can be sequestered in mine tailings.”

“In this project, we target kinetics,” Pan said. “Mine tailings contain a substantial amount of carbon-dioxide-reactive minerals such as olivine, which can be used as a carbon sink. It’s been done before, but at a much slower pace. Our method greatly accelerates the kinetics of carbon dioxide sequestration to achieve the result on an industrial scale in just four hours, rather than several years.”

The Michigan Tech team will work in partnership with Eagle Mine in upper Michigan, a subsidiary of Toronto-based Lundin Mining, and Polymet Mining in Minnesota.

“ARPA-E is looking for disruptive and scalable technologies, and then deploying them at an industrial site,” Pan said. “This is why two major mining companies, both with nickel mining operations, have agreed to join us in this effort. We’re glad to have both of them as supporters of this project.”

Carbon sinks can absorb and store more carbon dioxide than they release, keeping what is the most prevalent greenhouse gas emitted by human activity from entering the atmosphere with the goal to reduce global climate change.

In addition to reducing carbon dioxide in the atmosphere, MINER initiatives like the Michigan Tech project aim for a second goal that solves another important world challenge: extracting energy-relevant metals from silicate minerals for battery manufacturing.

“Eventually, our new methods could be put into practice in all types of mining if the ore mineralogy is favorable for carbon mineralization,” Pan said. “The outcome will not only be useful in the U.S. but in mining operations globally.”

ARPA-E seeks to develop market-ready technologies that will increase domestic supplies of critical elements required for the clean energy transition. Selected projects, led by universities, national laboratories and the private sector, aim to develop commercially scalable technologies that will enable greater domestic supplies of copper, nickel, lithium, cobalt, rare earth elements and other critical elements.

The project aligns with the state of Michigan’s plan to achieve carbon neutrality by 2050. Minnesota’s Climate Action Framework calls for reducing greenhouse gas emissions by 80% between 2005-2050.

Comments